“For many of our suppliers, we are an interesting and challenging project partner – particularly because we’re not all that big, which enables us to act quickly and flexibly. That said, we have high demands in terms of quality and sustainability,” explains Erwin Käch, Category Manager at V-ZUG for 30 years. For the past 15 years, he has managed the supplier relationship with the Finnish company Outokumpu, the world’s leading manufacturer of circular, low-carbon-emissions stainless steel. We already use this for the tubs and internal door parts of our dishwashers. A lot has changed since Käch started working at V-ZUG. “Due to our growing demand for products that support the circular economy, I spent a lot of time in recent years studying sustainable materials, and I learned quite a bit in the process. It changed my perspective – and sharpened it.”

Alternative energy for production

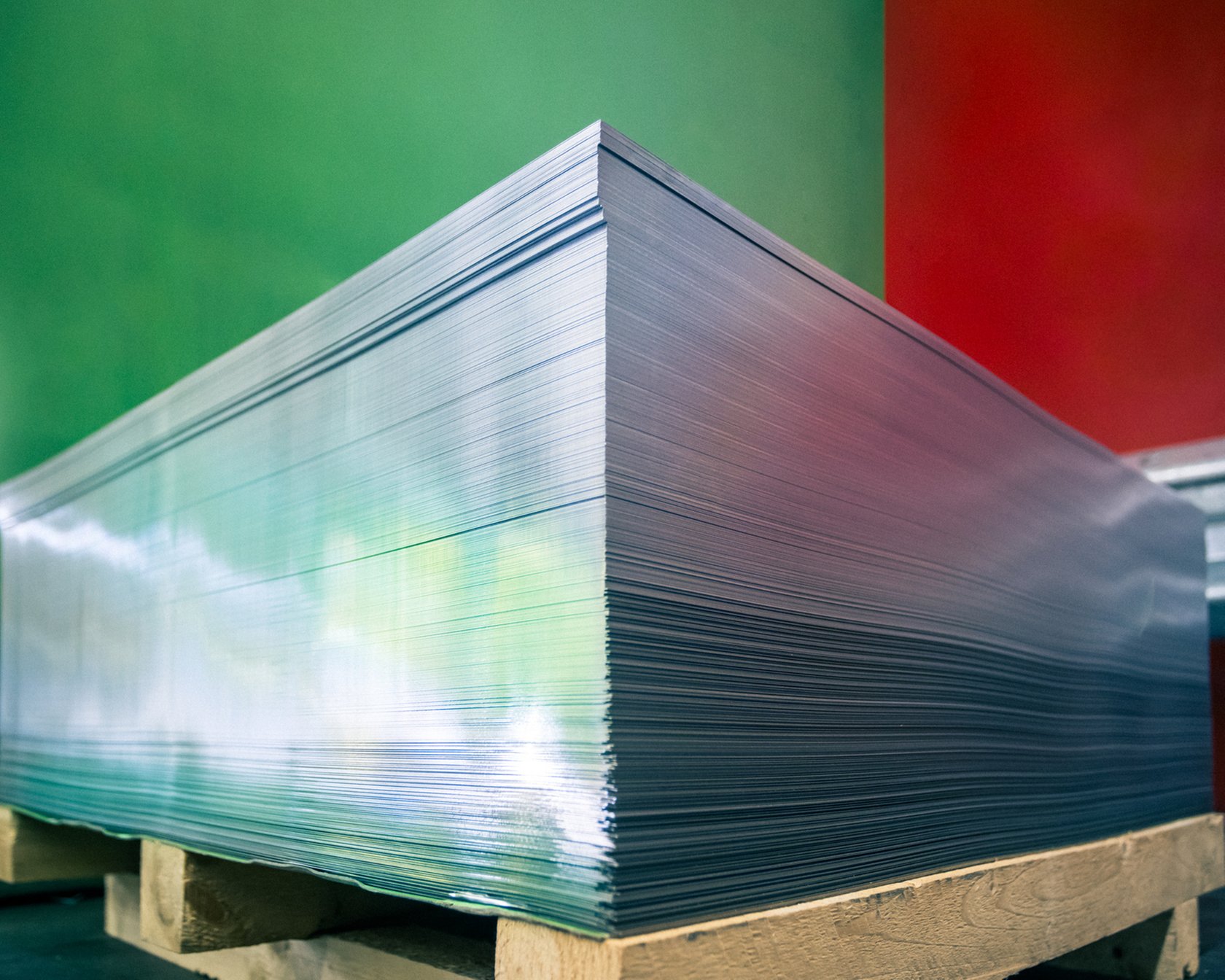

What does “low-carbon-emissions steel” mean in an industry that, according to the International Energy Agency (IEA), is responsible for 7 to 9 % of the global CO₂ emissions caused by humans? Wherever possible, Outokumpu uses alternative energy for production and more than 90 % recycled metal from its own scrap heap, which is Europe’s largest. At 0.5 t CO₂/t, what they call “Circle Green” steel has a CO₂ intensity that is nearly eleven times lower than the global average for steel used in industry. That is also helping to reduce the CO₂ component of our Scope 3 emissions. However, steel that is more environmentally friendly is expensive and thus not very competitive. “We want to change that. As a pilot customer, we are working closely with Outokumpu, helping to scale the Finnish company’s technology and make it more financially attractive,” explains Käch. We are financing the added costs of Circle Green steel through our CO₂ fund.