When V-ZUG decided to stay and invest in Zug – one of the most populated and expensive areas of Switzerland – the impact on the community and the sustainability of production facilities were two of the main factors to consider, for both managers and architects. And so the concept of a vertical factory was brought to the table. “Verticalisation means that the production areas are no longer housed on a single floor. Instead, they are distributed across different levels,” explains Markus Estermann, Head of Industrial Automation at V-ZUG. “No longer spread across the site, they are located over six floors.” The advantage is that distances are shorter, which in turn helps to optimise processes. Using automated logistics also allows the company to streamline movements: shorter chains lead to higher efficiency.

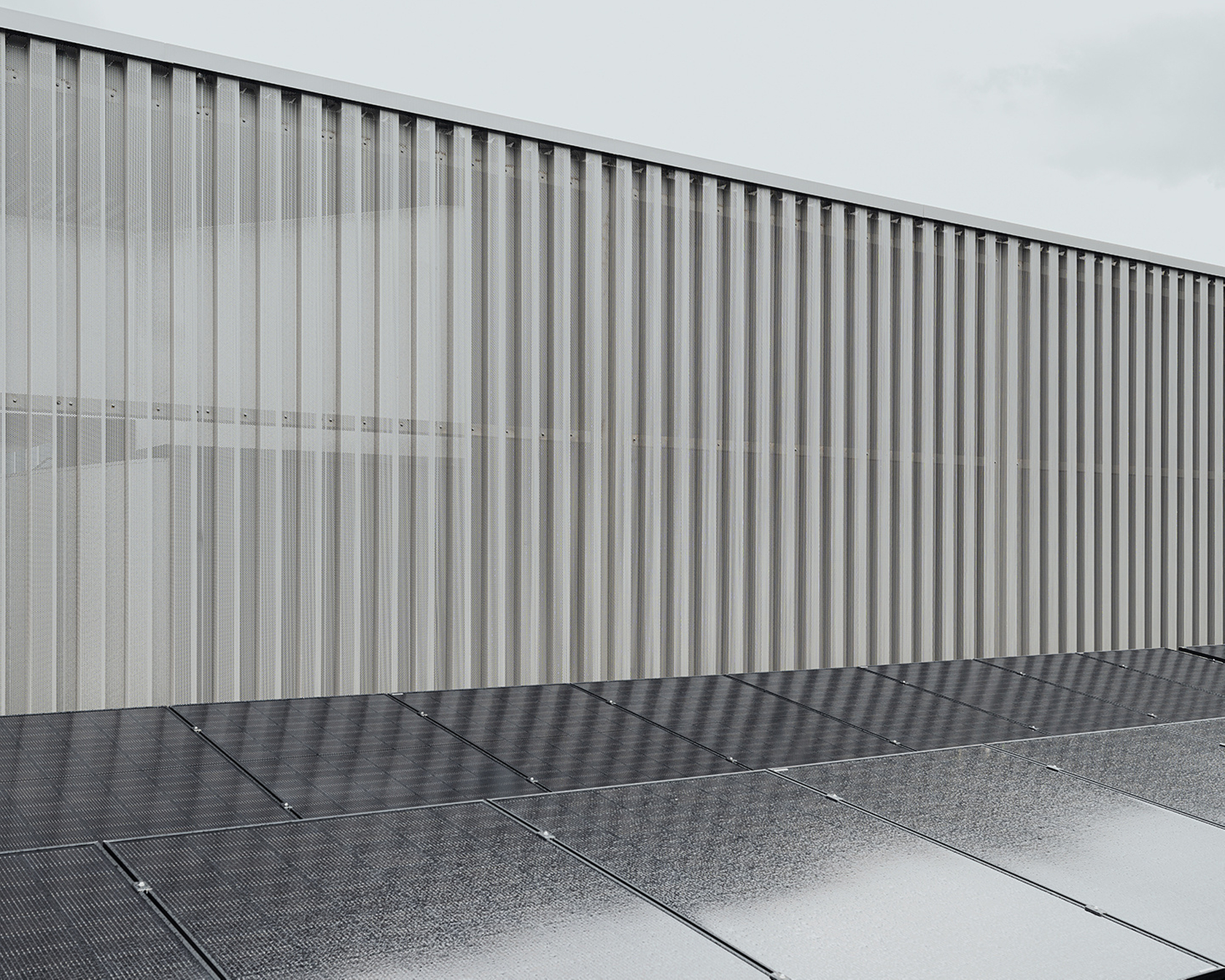

The vertical factory allows V-ZUG to reduce its footprint in Zug to around half of the original size. “We can save space and at the same time ensure that our ambitions for growth are achievable,” says Adrian Theiler, Chief Operations Officer. “It’s a generational change for the production and logistics facilities which contributes significantly to the modernisation of the company as a whole.” Speaking of innovation: As part of the Multi Energy Hub, Zephyr Ost utilises CO2-neutral energy for heating and cooling and produces electricity using photovoltaic systems on all possible locations on the roof.